产品类别

Product category

- 闪点系列Flash Poin ...

- 凝点倾点冷滤点浊点冰点系列P ...

- 粘度系列Viscosity ...

- 清洗机系列Cleaning ...

- 抗、破乳化系列Anti, e ...

- 微量水分系列Trace mo ...

- 界面张力系列Interfac ...

- 酸碱值系列PH series

- 锈蚀腐蚀系列Rust cor ...

- 石油产品密度系列Petrol ...

- 润滑油泡沫性能系列Lubri ...

- 空气释放值系列Air rel ...

- 恒温水浴系列Water ba ...

- 石油产品水分系列Petrol ...

- 绝缘油介电强度系列Insul ...

- 自燃点系列Ignition ...

- 绝缘油含气量系列Insula ...

- 体积电阻率和介质损耗系列Vo ...

- 电气绝缘油腐蚀性硫Elect ...

- 锥入度系列Penetrati ...

- 硫含量系列Sulfur co ...

- 石油产品机械杂质系列Mech ...

- 水溶性酸及碱系列Water- ...

- 馏程蒸馏系列Distilla ...

- 氧化安定性系列 Oxidat ...

- 蜡、胶质、沥青质含量系列Wa ...

- 石油产品烃类系列Petrol ...

- 实际胶质系列Gum seri ...

- 外投制冷器系列Foreign ...

- 恒温油浴锅系列Constan ...

- 石油产品苯胺点系列Anili ...

- SF6露点微水系列SF6 d ...

- 石油产品热值系列Calori ...

- 润滑油灰分系列Ash Ser ...

- 饱和蒸汽压系列Saturat ...

- 软化点系列Softening ...

- 润滑脂滴点系列Grease ...

- 残炭系列Char Serie ...

- 蒸发损失系列Evaporat ...

- 结晶点系列Crystal p ...

- 润滑油摩擦磨损性能试验机(四 ...

- 腐蚀性硫Corrosive ...

- 延伸度系列Elongatio ...

- 柴油总污染物Total di ...

- 柴、汽油辛烷值十六烷值Fue ...

- 红外光度测油仪photome ...

- 石油产品色度系列 Color ...

- 颗粒计数器系列Particl ...

- 气相色谱系列GC Serie ...

- 振荡仪系列Shaker se ...

- ICP光谱ICP spect ...

- 仪器配件Instrument ...

联系我们 contact us

- 电话:

- 13944694406

- 电话:

- 0432-66180758

- 传真:

- prtlz@163.com

- 地址:

- 吉林市昌邑区西山街199号吉林兰天国际商贸中心9号商铺0单元1至3层015号

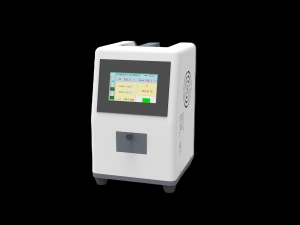

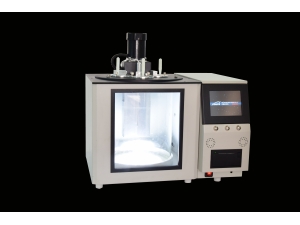

PCNQ601型全自动凝倾点测定仪PCNQ601 automatic condensate pour point tester

添加时间:2024-02-28

本仪器用于测定变压器油、柴油、润滑油、及各种机油的凝、倾点值,彩色液晶、中文操作界面,触摸式键盘、向导式菜单、动态图形工作界面。The instrument is used to determine the condensation, pour point v ...

PCNQ601型全自动凝/倾点测定仪

概 述

该仪器是以微处理器为控制核心,结合现代微电子技术,重新研制开发的新一代电子产品.采用真彩触摸液晶显示器为显示器件[增强型RAM内核,触控绝无卡顿现象], 中英文双语菜单、真彩GUI触摸屏界面设计,有良好的人机界面及操作信息。显示直观、操作简便(一定条件下完全可以不必看说明书便可很快的熟悉操作过程)、同时具备仪器控制自检及对用户设定的参数值有保存记忆功能。可以使操作更直观更简洁,有效的避免误操作。以Pt100金属铂电阻作为温度传感器,采用软硬件线性化技术,使测量更准确,测温精度更高。采用半导体制冷技术,制冷深度可达-65℃,制冷速度快。整个试验过程全部实现智能化、自动化,自动记录及打印结果。能够记忆以往的100项分析结果。

配合我公司石油分析仪器综合管理平台的〈系统管理〉、〈档案录入〉、〈检验操作〉、〈数据管理〉、〈帮助〉等操作,利用RS485 有线或无线接口,采用Modbus—RTU通讯协议实现计算机与仪器一机对多机通讯(即用一部台式或笔记本电脑[上位机]操控最大达128台我厂不同类型的分析仪器。)可利用电脑[上位机]操控仪器的启动,参数设定,及检验过程,适用于对有毒有害试样的分析工作;降低乃至于摆脱有毒有害物质对分析工作者身体的侵害。同时,为满足现代化企业管理的需要,可利用电脑[上位机]实现远程管理功能:对检验记录中的检验结果的数据统计、分析、存储、打印、报表等等。

整个仪器结构合理、测试速度快、测试范围宽、重复性和真实性好等等。操作简便、测量准确、工作可靠、广泛应用于石化、电力、铁路和科研等部门,是各实验室、化验室检测各类油品凝/倾点的专用设备。

技 术 指 标

- 测量范围:室温~-65℃

- 准 确 度: ±0.5%

- 制冷速度:10min>40℃

- 制冷深度:-65℃(冷却水温<15℃时)

- 冷却水压:0.5kg/cm2

- 重 复 性: 完全符合GB/T510标准 完全符合GB/T3535标准

- 显 示 器: 65536色真彩高灵敏触摸800*480液晶显示器。

- 通讯接口:无线或有线RS-485 [可选配]。

- 通讯协议: Modbus—RTU通讯协议。信息传输为9 位数据

- 异步多机通讯方式,以字节为单位。主和从之间传递的通讯数据格式:(1 位起始位,8 位数据位+1 位地址/数据标志位,1 位停止位)

- 波 特 率: 9600

- 软 件: 石油分析仪器综合管理平台[可选配]

- 电 脑: 可按客户需求选配。

- 使用环境:环境温度:10~30℃,相对湿度:小于80%RH

- 电 源: 220V.AC±10% 50HZ。

Pcnq601 automatic pour point tester

summary

The instrument is a new generation of electronic products with microprocessor as the control core and modern microelectronic technology. It uses true color touch LCD as display device [enhanced ram core, touch control is not stuck], Chinese and English bilingual menu, true color GUI touch screen interface design, with good man-machine interface and operation information. The display is intuitive and easy to operate (under certain conditions, you can quickly get familiar with the operation process without reading the manual). At the same time, it has the function of instrument control self-test and saving and memory for the parameter value set by the user. It can make the operation more intuitive and concise, and effectively avoid misoperation. The PT100 platinum resistance is used as the temperature sensor, and the software and hardware linearization technology is used to make the measurement more accurate and the temperature measurement accuracy is higher. Using semiconductor refrigeration technology, the refrigeration depth can reach - 65 ℃, and the refrigeration speed is fast. The whole test process is intelligent, automatic, automatic recording and printing results. They can remember 100 previous analysis results.

With the operation of "system management", "file entry", "inspection operation", "data management", "help" and other operations of our companys petroleum analysis instrument integrated management platform, RS485 is used With wired or wireless interface, Modbus RTU communication protocol is adopted to realize one machine to multi computer communication between computer and instrument (i.e. using a desktop or notebook computer [upper computer] to control up to 128 different types of analytical instruments in our factory.) The computer can be used to control the start-up, parameter setting and test process of the instrument, which is suitable for the analysis of toxic and harmful samples, and can reduce or even get rid of the harm of toxic and harmful substances on the body of analytical workers. At the same time, in order to meet the needs of modern enterprise management, we can use the computer [upper computer] to realize the remote management function: data statistics, analysis, storage, printing, report forms and so on.

The whole instrument has the advantages of reasonable structure, fast test speed, wide test range, good repeatability and authenticity, etc. It is widely used in petrochemical, electric power, railway and scientific research departments. It is a special equipment for testing the pour point of various oil products in laboratories and laboratories.

Technical index

Measurement range: room temperature to - 65 ℃

Accuracy: ± 0.5%

Cooling speed: 10min & gt; 40 ℃

Cooling depth: - 65 ℃ (cooling water temperature & lt; 15 ℃)

Cooling water pressure: 0.5kg/cm2

Repeatability: fully in line with GB / t510 standard

Fully comply with GB / t3535 standard

Display: 65536 color true color high sensitive touch 800 * 480 LCD.

Communication interface: wireless or wired RS-485 [optional].

Communication protocol: Modbus RTU communication protocol. Information transmission is 9-bit data

Asynchronous multi machine communication mode, in bytes. Communication data format transmitted between master and slave: (1 start bit, 8 bit data bit + 1 address / data flag bit, 1 stop bit)

Baud rate: 9600

Software: petroleum analysis instrument integrated management platform [optional]

Computer: optional according to customers needs.

Application environment: ambient temperature: 10 ~ 30 ℃, relative humidity: less than 80% RH

Power supply: 220 v.ac ± 10% 50 Hz.